The existing technologies used for hydrogen production do not address the key issues:

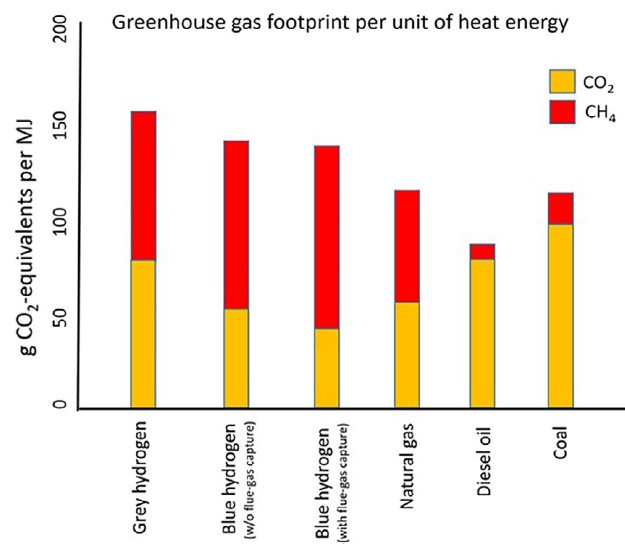

- Currently, over 90% of hydrogen used by the humanity are produced from methane through the thermal gas reforming. This so-called “brown” hydrogen leaves a substantial carbon trace. CCS steps turning it into the “blue” hydrogen drive the costs up, at the same time still failing to address the emissions issue, see R. Howarth, M. Jacobson. How green is blue hydrogen, 2021 https://www.researchgate.net/publication/353841896

Comparison of carbon dioxide equivalent emissions, R. Howarth, Mark Jacobson. How green is blue hydrogen, 2021

- “Green” hydrogen from electrolysis is extremely expensive, with EROI not exceeding 66%: https://manhattan.institute/article/green-hydrogen-a-multibillion-dollar-energy-boondoggle. To the major part, “green” hydrogen is being subsidized by the taxpayers (in Australia – by 70% to 75% https://reneweconomy.com.au/australia-has-38gw-of-green-hydrogen-in-pipeline-but-major-cost-falls-needed/ ). Besides, it does not resolve the carbon trace issue, either: https://www.anu.edu.au/news/all-news/%E2%80%9Cserious-threat%E2%80%9D-of-fugitive-emissions-with-hydrogen-plan – not to mention other environmental problems, e.g. those associated with de-salinization if water used for hydrogen production.

Only natural, a.k.a. “white” or “gold”, hydrogen seems to be the only plausible answer, providing cost-effective and net-zero solution. According to the number of sources, e.g. https://www.hydrogeninsight.com/innovation/analysis-will-natural-hydrogen-extracted-from-the-ground-be-the-next-global-gold-rush-/2-1-1346871, the lifting cost of natural hydrogen from Bougou-1 well in Mali is around US$0.50 per kg – six times lower than the commercially acceptable break-even threshold of US$3.00 per kg.

110m deep Bougou-1 well producing approx. 130 kg pday H2 since 2011. From https://hydroma.ca/activities-natural-hydrogen/